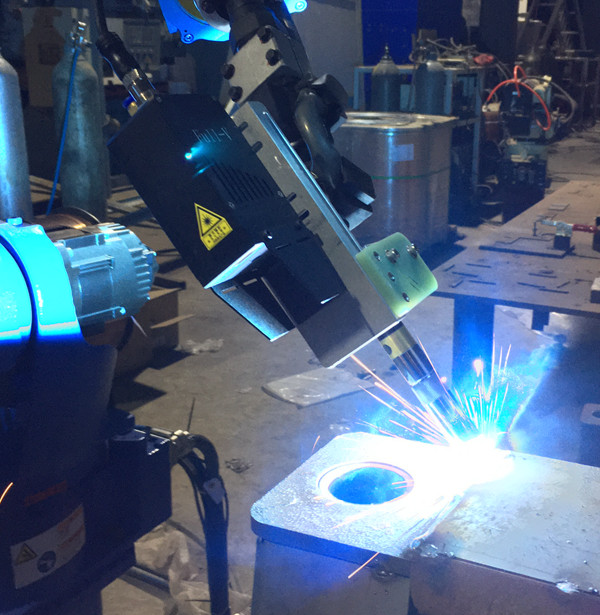

Mune chaiyo welding process, kuitira kudzivirira njodzi kana robhoti iri kushanda, mushandisi haabvumirwe kana kuti haafanire kupinda munzvimbo yekushanda yerobhoti, kuitira kuti mutyairi haakwanise kutarisisa iyo welding process munguva chaiyo uye kugadzirisa kwakakodzera. , saka kana mamiriro ezvinhu achinja, senge zvichiitika dimensional kukanganisa uye chinzvimbo kutsauka kweworkpiece panguva yewelding uye gungano muitiro, uye kudziyisa deformation yeworkpiece, iyo yejoini chinzvimbo inotsauka kubva munzira yekudzidzisa, inogona kukonzera welding kunaka kuderera. kana kutokundikana.

Ndeipi nguva yatinoda kushongedza robhoti yekushongedza nelaser kuona?

Mune arc welding, kana iko kukwenenzverwa kusingagone kuvimbiswa kusvika ± 0.3mm, zvinofanirwa kufunga nezve kushandiswa kwelaser positioning kana laser tracking.Kuti usarudze laser vision welding seam tracking system, iwe unofanirwa kutanga waona kana ichikanganisa chigadziriso chemidziyo, uye chechipiri, funga kana ichizokanganisa nguva yekurova.Kana zvese zvisirizvo, ipapo iyo laser inogona kunyatsobatanidzwa murobhoti yekushandira.

Iyo yakakosha yekuongorora musimboti we laser vision welding seam tracking

Iyo yakakosha musimboti welaser seam yekutevera yakavakirwa pane iyo laser triangle yekuyera nzira.Iyo laser inoburitsa mutsara welaser mwenje pamusoro peiyo workpiece, uye mushure mekupararira kwekuratidzira, iyo laser contour inoratidzwa paCCD kana CMOS sensor.Mutongi anobva agadzirisa uye anoongorora mifananidzo yakaunganidzwa kuti awane nzvimbo ye weld, iyo inoshandiswa kugadzirisa welding trajectory kana kutungamira welding.

Chii chinonzi laser tracking?

Laser yekutevera inoshandisa laser vision sensor kuti ione weld in advance pamberi petorch yewelding, uye inoverengera zvinzvimbo zvinorongeka zveyero yekuyera sensor kuburikidza ne pre-calibrated positional hukama pakati pe laser vision sensor ne torch.Munguva yewelding process, iyo robhoti yekudzidzisa chinzvimbo uye chinzvimbo che sensor inoverengerwa.Nzvimbo dzekuona dzinofananidzwa, uye kuverenga kutsauswa kwenzvimbo yenzvimbo inoenderana.Kana iyo welding pfuti yakarembera kuseri kwelaser mutsara inosvika panzvimbo yekuona inoenderana, kutsauka kunobhadharwa kune yazvino welding trajectory kuzadzisa chinangwa chekugadzirisa welding trajectory.

Chii chinonzi laser positioning?

Laser positioning ndiyo nzira yekushandisa laser sensor kuita chiyero chimwe chete chenzvimbo yekuyerwa uye kuverenga nzvimbo yeinongedzo.Kazhinji, kana paine kapfupi welding seam kana kushandiswa kwelaser tracking kuchikanganisa chigadziriso chekushandisa, musono welding unogadziriswa muchimiro chelaser positioning.Kuenzaniswa nelaser tracking, basa relaser positioning riri nyore, kuita uye kushanda Izvo zvakare zviri nyore.Nekudaro, sezvo yaonekwa pekutanga uye yozoiswa weld, iyo yekumisikidza haina kukodzera welding workpieces ine yakanyanya kupisa deformation uye irregular welds isiri mitsetse yakatwasuka kana arcs.

Nguva yekutumira: Oct-22-2022