China 6 Axis 1800mm Arm inosvika otomatiki Steel MIG Welding Robotic Arm

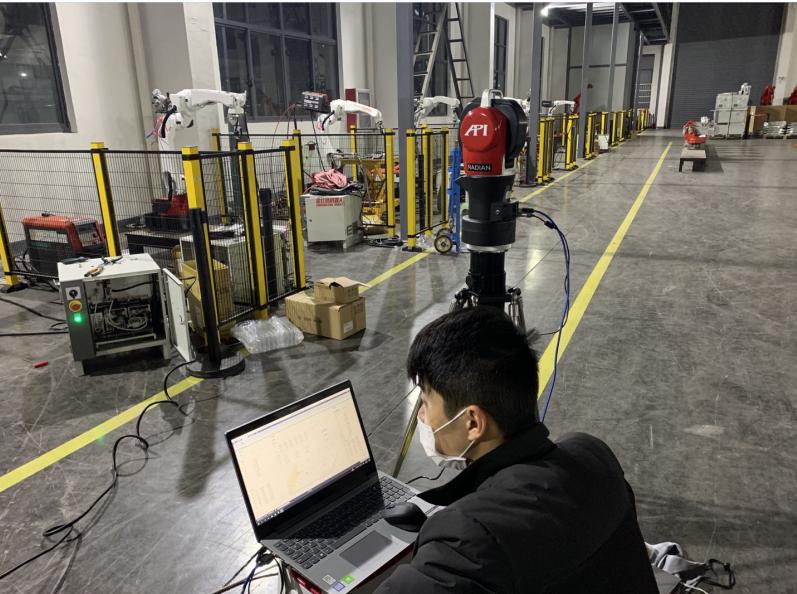

LASER CALIBRATION TEST REPOSITIONING KUKWANA

JHY inoshandisa laser calibration nzira yekuyedza iyo inodzokororwa yekumisikidza kurongeka kwerobhoti.Mushure mekuedzwa kwakawanda, iyo yakadzokororwa yekumisikidza kurongeka kwerobhoti yedu yakakwira zvakanyanya kupfuura ± 0.08mm.

SHANDISA MABRAND EKUPEDZISIRA ZVINHU ZVINOGONESA

Robot core accessories senge servo mota, RV reducer, harmonic reducer, servo drive uye zvichingodaro zvese zvinoshandisa maChina emhando yepamusoro, ayo akaedzwa nekushandisa kwedu kwenguva refu kuona kuti akakodzera marobhoti edu.

SIMPLE MATINANCE

Maintenance iri nyore, Maererano negwaro rekugadzirisa rakapihwa nesu vatengi pachavo vanogona kushanda nyore.

AFTER SALE GUARANTEE

Wese mutengi ane yake mushure mekutengesa sevhisi boka.Kana iwe uchida chero mushure mekutengesa rubatsiro, Pls bvunza chero nguva.Mainjiniya edu ehunyanzvi achazvigadzirisa munguva pfupi pfupi.Chiripo ndechekuti zvese zvakasununguka.

| Welding parameters inoreva simbi yakapfava uye yakaderera alloy simbi | |||||||||

| type | ndiro | Waya dhayamita | midzi gap | welding current | welding voltage | welding speed | Bata tip-workpiece chinhambwe | Kuyerera kwegasi | Welding angle |

| T-shaped butt welding | 1.0 | 0.8 | 2.5~3 | 70~80 | 17~18 | 8~10 | 10 | 10~15 | 45° |

| 1.2 | 1.0 | 3~3.5 | 85~90 | 18~19 | 8~10 | 10 | 10~15 | 45° | |

| 1.6 | 1.0,1.2 | 3~3.5 | 100~110 | 18~19.5 | 8~10 | 10 | 10~15 | 45° | |

| 2.0 | 1.0,1.2 | 3~3.5 | 115~125 | 19.5 ~ 20 | 8~10 | 10 | 10~15 | 45° | |

| 2.3 | 1.0,1.2 | 3~3.5 | 130~140 | 19.5-21 | 8~10 | 10 | 10~15 | 45° | |

| 3.2 | 1.0,1.2 | 3.5~4 | 150~170 | 21~22 | 7.5~8 | 15 | 15~20 | 45° | |

| 4.5 | 1.0,1.2 | 4.5~5 | 180~220 | 21~23 | 6.5–7.5 | 15 | 15~20 | 45° | |

| 1.2 | 5~5.5 | 200~250 | 24~26 | 6.5~8 | 10~15 | 10~20 | 45° | ||

| 6 | 1.2 | 5~5.5 | 230~260 | 25~27 | 6.5–7.5 | 20 | 15~20 | 45° | |

| 6 | 220~250 | 25~27 | 5.5~7.5 | 13~18 | 10~20 | 45° | |||

| 4~4.5 | 270~300 | 28~31 | 10~11.5 | 13~18 | 10~20 | 45° | |||

| 8,9 | 1.2,1.6 | 6~7 | 270~380 | 29~35 | 6.5–7.5 | 25 | 20~25 | 50° | |

| 8 | 1.2 | 5~6 | 270~300 | 28~31 | 9~10 | 13~18 | 10~20 | 45° | |

| 1.2 | 7~8 | 260~300 | 26~32 | 4~5.5 | 15~20 | 10~20 | 50° | ||

| 1.6 | 6.5~7 | 300~330 | 30~34 | 5~5.5 | 15~20 | 10~20 | 50° | ||

| 12 | 1.2,1.6 | 7~8 | 270~380 | 27~35 | 4.5~6.5 | 20~25 | 20~25 | 50° | |

| 1.2 | 7~8 | 260~300 | 26~32 | 4~5.5 | 15~20 | 10~20 | 50° | ||

| 1.6 | 6.5~7 | 300~330 | 30~34 | 5~6 | 15~20 | 10~20 | 50° | ||

Cherechedza:

1. MIG welding inoshandisa inert gas, inonyanya kushandiswa kugadzira aruminiyamu uye alloys ayo, mhangura uye alloys ayo, titanium uye alloys ayo, pamwe nesimbi isina tsvina nesimbi isingadziviriri kupisa.MAG welding uye CO2 gasi yakadzivirirwa welding inonyanya kushandiswa kugadzira kabhoni simbi uye yakaderera alloy yakakwirira simba simbi.

2. Izvo zviri pamusoro apa ndezvekutarisa chete, uye zviri nani kuwana iyo yakakwana welding process paramita kuburikidza nekuyedza verification.Iri pamusoro apa waya madhayamita anobva pamienzaniso chaiyo.