China 6 axis 1500m robhoti ruoko simbi furemu mig welding robhoti

Patents uye Dhizaini

6-axis yechipiri kutapurirana Yakashandurwa kune maviri mabhandi ekubatanidza, yakawedzera chiyero chekutumira, uye yakagadzirisa dambudziko re6- axis inofamba nekukurumidza uye isina kururama.Iyo yechitanhatu-axis inobuda disc yakagadzirwa isina magiya, iine yakakwirira-chaiyo yekufambisa michina, iyo inovandudza mafambiro eiyo axis yechitanhatu…Parizvino tine anopfuura makumi matatu ane hukama patents erobhoti rewelding.

Software Configuration For Arten Pro Welding Machine

| Model | Software package | Welding zvinhu | Technique type | Synergy | Special synergy |

| Artsen Pro500P(R) | PP | Solid kabhoni simbi, yakasimba Stainless | Short-circuiting kufambisa, pfupi arc pulse | Ehe | no |

Welding Torch Technicalspecification

Kutonhodza nzira:Liquid kutonhora

Rating:550A CO2,500A MIXED GAS M21(ISO14175)

Basa kutenderera: 100%

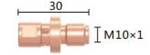

Waya dhayamita: 0.8 ~ 1.6MM

Torch geometries: 22°,36°,45°,180°

* Inoshanduka goose mutsipa ine mvura yekumisa basa.Zviri nyore kuchinja goose mutsipa uye kuita kugadzirisa.

* Wire brake basa (kusarudza)

* Nekuvhunduka sensor (sarudzo)

* Dzakawanda sarudzo dzeakasiyana goose mutsipa kona uye kureba.

*Ivepo kune yakakurumbira waya feeder yekubatanidza senge.Lincoln Panasonic European maitiro nezvimwe.

| PRO akatevedzana torch Spare Zvikamu | ||

| AIHWA. | Zvikamu | Pics. |

| 1 | Bata Zano | |

| 2 | Tip Holder | |

| 3 | Nozzle | |

| 4 | Nozzle Holder | |

| 5 | Nozzle Holder Cap | |

| 6 | Inner Wire Feeding Tube | |

| 7 | Shunt | |

| 8 | Insulation mhete | |

| 9 | Goose neck |  |

| Welding parameters inoreva simbi yakapfava uye yakaderera alloy simbi | |||||||||

| type | ndiro | Waya dhayamita | midzi gap | welding current | welding voltage | welding speed | blunt edge | Kuyerera kwegasi | |

| Butt yakaita seV | 12 | 1.2 | 0~0.5 | zvekunze1 | 300~350 | 32~35 | 5~6.5 | 4~6 | 20~25 |

| zvemukati 1 | 300~350 | 32~35 | 7.5–8.5 | 20~25 | |||||

| 1.6 | zvekunze1 | 380~420 | 36~39 | 5.5~6.5 | 20~25 | ||||

| zvemukati 1 | 380~420 | 36~39 | 7.5–8.5 | 20~25 | |||||

| 16 | 1.2 | 0~0.5 | zvekunze1 | 300~350 | 32~35 | 4~5 | 4~6 | 20~25 | |

| zvemukati 1 | 300~350 | 32~35 | 5~6 | 20~25 | |||||

| 1.6 | zvekunze1 | 380~420 | 36~39 | 5~6 | 20~25 | ||||

| zvemukati 1 | 380~420 | 36~39 | 6~6.5 | 20~25 | |||||

| Cherechedza: 1. MIG welding inoshandisa inert gas, inonyanya kushandiswa kugadzira aruminiyamu uye alloys ayo, mhangura uye alloys ayo, titanium uye alloys ayo, pamwe nesimbi isina tsvina nesimbi isingadziviriri kupisa.MAG welding uye CO2 gasi yakadzivirirwa welding inonyanya kushandiswa kugadzira kabhoni simbi uye yakaderera alloy yakakwirira simba simbi. 2. Izvo zviri pamusoro apa ndezvekutarisa chete, uye zviri nani kuwana iyo yakakwana welding process paramita kuburikidza nekuyedza verification.Iri pamusoro apa waya madhayamita anobva pamienzaniso chaiyo. | |||||||||